Push button switches work through pressing a button. It’s a simple yet effective method of controlling devices like doors, lamps, and alarms. The push button switches can be temporary, meaning that the switch is returned to its initial position when released, or they can be kept in that they remain in the state of being active until it is reset manually. The type of switch depends on the application and desired level of control.

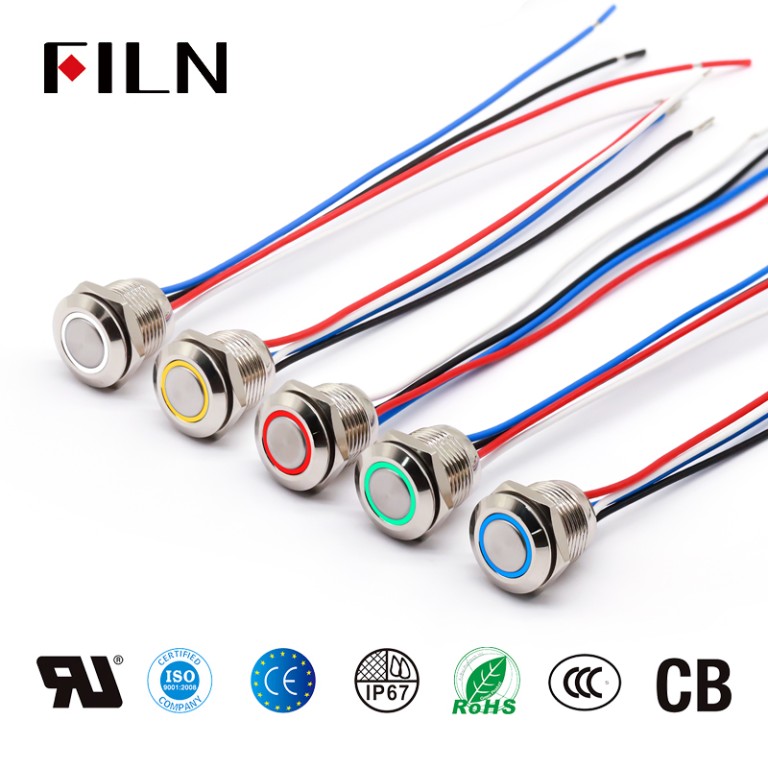

Image credit: indicatorlight.com

Push Button 12V Switches Future of Power: Future of Power

They are utilized in many different applications such as automotive, marine and industrial. The switches that work at 12 volts, make them ideal for vehicles or boats, or any other equipment that needs an effective, reliable control system. The 12V push button is accessible in various configurations like latching or momentary. They are suitable for many different devices from simple lights to more complicated systems.

The ease of use is among the major advantages of 12V push-button switches. They are simple to install and require little wiring. They’re an excellent option for DIY enthusiasts as well as professionals. In addition, 12V push button switches are extremely reliable and can stand up to the pressures of use for long periods they are a good choice for applications where durability is vital.

Persistence is key when it involves latching push-button switches

They remain in their activated condition until they are reset manually. They are perfect for devices that needs to remain in a state of either on or off for a longer duration. Latching push button switches are often used in control systems for industrial use which are used to control motors, pumps and other equipment.

Latching push-button switches are famous for their ability to give a continuous signal. The switch remains in its position regardless of when you release the button. This provides a reliable control signal. The push button switches that latch can be utilized for many different applications. They can be used for control systems that are simple as well as complex systems that require a number of switches and relays.

Marine Push Buttons: They can withstand the elements

Marine push-button switches are made to withstand the tough conditions encountered in marine environments. They are resistant to corrosion. They are generally made out of stainless steel, bronze, or other materials. Marine push button switch are used in a variety of purposes, including navigation as well as safety and communication systems.

To design marine push button switches it is important to be in a position to stand up to saltwater’s corrosive influence. To tackle this problem, manufacturers use specialized coatings and materials that offer an extremely high degree of protection from corrosion. The push button switches for marine use can be able to withstand high usage and are extremely durable. This is why they are a good choice for those who require safety.

Waterproof Push Button Switches: Sealing Out the Elements

Switches that have waterproof buttons are made to provide an excellent amount of protection from humidity and water. The switches are usually covered with an impervious membrane or coating, which prevents water from getting into the switch, causing damage. Waterproof push buttons are employed for various applications like outdoor and marine industrial systems as well as in the marine industry.

The humble push button has advanced a lot from its humble start. They’re now highly sophisticated solutions for many applications such as industrial, automotive and marine. 12V push button switches, latching push button switch, marine push button switch, and waterproof push button switch are just a few examples of the many types of switches available. When you know the various types of push button switches and their uses engineers and designers can design more efficient, reliable and safe systems that meet the needs for a range of industries. The push button switch can be used to control systems in a variety of ways, be it simple controls that turn off and on, or an advanced one that utilizes multiple switches and relays.

The push button switches are predicted to develop as technology advances. They’ll be incorporating new materials, wireless communications and IoT. Whether you’re an engineer, designer or a DIY enthusiast, knowing how to use these components is essential to designing effective and robust systems. Filn’s modern designs mean that the future of push button switches holds many possibilities.